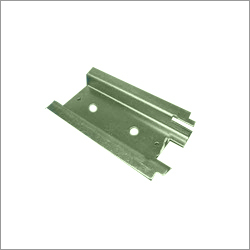

Sheet Metal Stamping Parts

Sheet Metal Stamping Parts Specification

- Mount Type

- Screw Mount, Rivet Mount

- Coating Type

- Electroplated, Painted, Zinc-Coated

- Shape

- Rectangular, Custom Geometries

- Surface Finishing

- Matte, Glossy, Brushed, Polished

- Dimension (L*W*H)

- Custom as per drawing, typical range 50 mm x 30 mm x 1.2 mm

- Usage

- Mechanical Assembly, Automotive Parts, Electrical Enclosures

- Components

- Brackets, Covers, Shields, Mounting Plates

- Application

- Automotive Industry, Electronics, Construction

- Hole Size

- 2 mm to 12 mm

- Weight

- Varies as per design; approx. 30 g to 180 g

- Material

- Stainless Steel, Mild Steel, Aluminum

- Tolerance

- 0.05 mm

- Thickness

- 0.5 mm to 3 mm

- Capacity

- High-volume production (up to 100,000 parts/month)

- Surface Treatment

- Galvanization, Powder Coating, Anodizing

- Making Process

- Stamping, Pressing

Sheet Metal Stamping Parts Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1-4 Week

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Sheet Metal Stamping Parts

Comprehensive Customization and Quality

Every stamped metal part is precisely crafted according to your design specifications, with support for custom dimensions, thickness (0.5 mm to 3 mm), edge profiles, and surface finishes. Choose from a spectrum of colors and surface treatmentsensuring your parts offer both functional performance and an appealing appearance.

Robust Performance for Industrial Applications

Our components are designed to handle the rigors of automotive, electrical, and construction environments. With high corrosion resistance and thermal stability up to 200C (depending on the material), these parts ensure long-term reliability even in harsh conditions.

Efficient Production and Reliable Supply

Benefit from our high-volume capacityup to 100,000 parts per monthand swift lead times of 715 days post order confirmation. Careful packaging in corrugated boxes or wooden pallets guarantees products arrive safely and ready for integration into your assembly lines.

FAQs of Sheet Metal Stamping Parts:

Q: How is the manufacturing process for your sheet metal stamping parts carried out?

A: Our manufacturing process involves precision stamping and pressing operations using punching forces up to 80 tons. We utilize advanced CAD/CAM support for design and tooling, and finish each part with deburred, chamfered edges and the selected surface treatment to meet specific performance and aesthetic requirements.Q: What materials and finishes are available for these sheet metal parts?

A: We manufacture parts using stainless steel, mild steel, or aluminum. Surface finishes include galvanization, powder coating, anodizing, and various coatings such as electroplating or zinc-coating. Available finishes range from matte, glossy, brushed to polished, and custom colors can be provided upon request.Q: When can I expect delivery after placing an order?

A: The standard lead time for production is 7 to 15 days from order confirmation, depending on order volume and design complexity. We also support high-volume orders, ensuring timely delivery even for large projects.Q: Where can these sheet metal stamping parts be used?

A: Our stamped metal components are widely used in the automotive industry, electronics manufacturing, and construction sectors. Typical applications include brackets, covers, shields, mounting plates, and various structural or enclosures for machinery.Q: What are the benefits of using your corrosion-resistant stamped metal parts?

A: Thanks to corrosion-resistant coatings and premium materials, these parts maintain structural integrity and appearance over extended periods, even in challenging environmental conditions. This longevity reduces maintenance costs and enhances product reliability.Q: How are the parts packaged for shipment?

A: We package all stamped metal parts securely in corrugated boxes or wooden pallets, depending on quantity and destination. This ensures the parts remain undamaged during transit and are delivered in optimal condition for immediate use or assembly.Q: What customization and design services do you offer?

A: Our in-house design team provides CAD/CAM support to help realize your specific requirements. We offer customization in dimensions, thickness, colors, surface finishes, and can accommodate a variety of hole sizes and mounting types based on your drawings and specifications.

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1-4 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Parts Category

Industrial Precision Stamping Part

Minimum Order Quantity : 1000 Pieces

Material : Stainless Steel

Usage : Hardware Fittings

Dimension (L*W*H) : 45 mm x 30 mm x 8 mm

Making Process : Other, Precision Stamping

Application : Industrial Machinery

Industrial Sheet Metal Pressed Parts

Minimum Order Quantity : 2000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Usage : Structural and fastening purposes in industrial assemblies

Dimension (L*W*H) : Custom as per drawing or sample, typically ranging from 50mm x 50mm x 2mm to 500mm x 400mm x 6mm

Making Process : Other, Pressing, Stamping, Punching, Cutting

Application : Automotive, Electrical, Machinery, Construction

Sheet Metal Pressed Parts

Minimum Order Quantity : 1000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Usage : Metal Enclosures, Brackets, Covers, Automotive Parts

Dimension (L*W*H) : Custom as per design/drawing

Making Process : Other, Stamping/Pressing, Cutting, Bending, Punching

Application : Automotive, Electrical, Machinery, Construction

Sheet Metal Components

Minimum Order Quantity : 1000 Pieces

Material : Aluminum, Copper, Stainless Steel, Steel

Usage : Industrial

Dimension (L*W*H) : As per customer requirement Millimeter (mm)

Making Process : Stamping

Application : Engineering, Automobile, Electrical Etc.

GST : 27AACPM2868E1ZP

Send Inquiry

Send Inquiry Send SMS

Send SMS