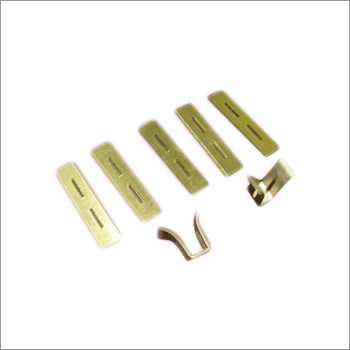

Brass Stamped Components

Brass Stamped Components Specification

- Thickness

- 0.2 mm to 4 mm

- Surface Treatment

- Nickel, Tin, Silver Plating or Natural Brass Finish

- Machining Method

- Stamping, Punching, Bending

- Max Tolerance

- 0.05 mm

- Weight (kg)

- 0.005 to 0.08 kg (depending on size)

Brass Stamped Components Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Mumbai

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Brass Stamped Components

We have marked a distinct position in the domain by manufacturing and supplying Brass Stamped Components. Offered components are manufactured by superior quality brass and highly advanced technology under the guidance of our precision engineers keeping in mind the set industrial norms. These are available in various sizes and specifications suiting to the specific demands of our customers. Brass Stamped Components are used in electrical, electronics, telecommunication and automotive industry. We offer these components at reasonable prices.

Features:

- High tensile strength

- Dimensional accuracy

- Light weight and durable

Custom-Shaped Solutions for Multiple Industries

Our brass stamped components are designed to cater to a variety of sectors, including electrical, electronics, automotive, and industrial assemblies. Manufactured as per client specifications, these components offer flexibility in shape, thickness, and plating options, enabling seamless integration into diverse assembly lines. Each item is finished with anti-corrosive treatments, extending operational life in demanding environments.

Precision Manufacturing and Quality Assurance

Using advanced stamping, punching, and bending techniques, our components are fabricated with consistent precision. We strictly adhere to a maximum tolerance of 0.05 mm, ensuring each component meets stringent quality standards. Every batch undergoes thorough inspection to guarantee compliance with RoHS and REACH directives, as well as customer-specific requirements.

High Volume Capacity and Secure Packaging

With a robust monthly output of up to 100,000 pieces, we are equipped to fulfill bulk orders efficiently. Whether opting for box or carton packing, your components arrive safely and organized. Our packaging solutions are designed to prevent damage during transit, maintaining the integrity of each piece from our facility in India to your doorstep.

FAQs of Brass Stamped Components:

Q: How are the brass stamped components manufactured?

A: The components are produced using advanced stamping, punching, and bending methods, based on customer-provided drawings or specifications. State-of-the-art machinery ensures high precision and consistency, achieving a maximum tolerance of 0.05 mm for each part.Q: What applications are these brass components suitable for?

A: These components are ideal for use in electrical, electronics, automotive, and industrial assemblies. Their durability, anti-corrosive finishes, and customizable shapes make them compatible with various assembly requirements across these industries.Q: When can I expect my order to be ready for shipment?

A: Our production capacity allows us to manufacture up to 100,000 pieces per month. Lead times depend on order size and customization, but standard orders are typically ready within a few weeks. Shipping is arranged promptly in box or carton packing for safe delivery.Q: Where are these brass stamped components manufactured?

A: All our brass stamped components are manufactured in India, following international standards for material quality and compliance, such as RoHS and REACH.Q: What surface finish options are available for these components?

A: We offer a range of surface treatments including nickel, tin, and silver plating, as well as a natural brass finish. All finishes provide enhanced resistance to corrosion and wear, improving the longevity of the components.Q: What are the benefits of using high-quality IS 319 and CZ121 brass material?

A: IS 319 and CZ121 grades of brass offer excellent mechanical strength, corrosion resistance, and electrical conductivity. This ensures reliable performance, long-lasting durability, and superior quality for critical applications.Q: Can the components be customized according to my requirements?

A: Yes, we support OEM and ODM customization. Clients can specify size, thickness (0.2 mm to 4 mm), shape, finish, and other parameters to perfectly match their project needs.

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Automotive Brass Component Category

Brass Component

Minimum Order Quantity : 1000 Pieces

Machining Method : CNC Turning & Milling

Thickness : 2 mm

Surface Treatment : Other, Polished Brass

Weight (kg) : 0.065 kg

Industrial Brass Component

Price Range 10.00 - 100.00 INR / Set

Minimum Order Quantity : 15000 Pieces

Machining Method : CNC Machining

Thickness : 5 mm

Surface Treatment : Other, Polished

Weight (kg) : 0.12

GST : 27AACPM2868E1ZP

Send Inquiry

Send Inquiry Send SMS

Send SMS