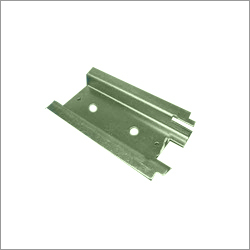

Industrial Precision Stamping Part

Industrial Precision Stamping Part Specification

- Application

- Industrial Machinery

- Coating Type

- Zinc Coated

- Usage

- Hardware Fittings

- Mount Type

- Panel Mount

- Components

- Single Piece

- Shape

- Rectangular

- Surface Finishing

- Deburred, Smooth Finish

- Dimension (L*W*H)

- 45 mm x 30 mm x 8 mm

- Hole Size

- 6 mm

- Weight

- Approx. 25 grams

- Material

- Stainless Steel

- Tolerance

- 0.05 mm

- Thickness

- 1.5 mm

- Capacity

- High Volume Production

- Surface Treatment

- Electroplating

- Making Process

- Precision Stamping

Industrial Precision Stamping Part Trade Information

- Minimum Order Quantity

- 1000 Pieces

- FOB Port

- Mumbai

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- as per requirements

- Main Domestic Market

- Maharashtra

About Industrial Precision Stamping Part

We have carved a niche in the market as a prime organization engaged in manufacturing and supplying Industrial Precision Stamping Part. This part is used in industrial heavy duty machinery and equipments like agriculture, construction and power generation.Best quality steel alloys and mild steel are used to manufacture this part. The part we provide includes mounting brackets, metal housings, interior components and more. Industrial Precision Stamping Part goes through different processes like blanking, coining, bending, drawing, forming and piercing.

Features:

- Rugged construction

- Able to withstand high impact

- Corrosion proof

Exceptional Mechanical Strength and Corrosion Resistance

Choosing this precision-stamped component ensures superior mechanical hardness (HRB 80-90) and top-notch corrosion resistance, thanks to meticulous material selection and advanced surface treatments. The mirror-polish and zinc coating offer both visual appeal and reliable performance, even in demanding industrial environments. Built for longevity, these parts minimize maintenance and replacement needs.

Advanced Progressive Die Stamping Production

Manufactured via progressive die stamping, each unit displays consistent quality and precise dimensions. This automated process enables high-volume output while maintaining tight tolerances (0.05 mm). As a result, customers receive parts with uniform thickness and finishing, suitable for integration within various machinery assemblies.

FAQs of Industrial Precision Stamping Part:

Q: How is the corrosion resistance of the stamping part ensured during manufacturing?

A: Corrosion resistance is achieved through the use of stainless steel combined with zinc electroplating. This multi-layered approach protects the part from rust and environmental degradation, making it highly suitable for industrial applications.Q: What is the production process for this industrial stamping part?

A: The part is manufactured using progressive die stamping, which involves the continuous forming of the stainless steel strip via sequential dies. This method guarantees precise dimensions and efficient high-volume production.Q: When can clients expect delivery after placing an order for customized stamping parts?

A: Lead time for production and delivery is typically 2-4 weeks, depending on order volume and customization requirements. The parts are shipped in export-grade corrugated boxes to protect them during transit.Q: Where is this stamping part manufactured and supplied from?

A: This precision stamping part is produced and supplied by a certified manufacturer in India, adhering to ISO 9001:2015 standards for quality assurance.Q: What customization options are available for this stamping part?

A: The part can be customized according to client drawings and specifications, including adjustments to dimensions, hole sizes, coatings, and surface finishes, all within tight tolerances to meet specialized requirements.Q: How is the packaging handled for international shipments?

A: For export, the parts are securely packed in export-grade corrugated boxes, ensuring protection against damage during transit and compliance with international shipment requirements.Q: What are the primary benefits of using this stamping part in industrial machinery?

A: The key benefits include excellent corrosion resistance, high dimensional accuracy, customized fit, and durable mirror-polished finish. These properties collectively enhance machinery reliability, reduce maintenance, and extend component life in hardware fittings.

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 1 Week

- Main Domestic Market

- Maharashtra

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Parts Category

Industrial Sheet Metal Pressed Parts

Minimum Order Quantity : 2000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Application : Automotive, Electrical, Machinery, Construction

Making Process : Other, Pressing, Stamping, Punching, Cutting

Usage : Structural and fastening purposes in industrial assemblies

Dimension (L*W*H) : Custom as per drawing or sample, typically ranging from 50mm x 50mm x 2mm to 500mm x 400mm x 6mm

Sheet Metal Stamping Parts

Minimum Order Quantity : 10000 Pieces

Material : Other, Stainless Steel, Mild Steel, Aluminum

Application : Automotive Industry, Electronics, Construction

Making Process : Other, Stamping, Pressing

Usage : Mechanical Assembly, Automotive Parts, Electrical Enclosures

Dimension (L*W*H) : Custom as per drawing, typical range 50 mm x 30 mm x 1.2 mm

Sheet Metal Pressed Parts

Minimum Order Quantity : 1000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Application : Automotive, Electrical, Machinery, Construction

Making Process : Other, Stamping/Pressing, Cutting, Bending, Punching

Usage : Metal Enclosures, Brackets, Covers, Automotive Parts

Dimension (L*W*H) : Custom as per design/drawing

Sheet Metal Components

Minimum Order Quantity : 1000 Pieces

Material : Aluminum, Copper, Stainless Steel, Steel

Application : Engineering, Automobile, Electrical Etc.

Making Process : Stamping

Usage : Industrial

Dimension (L*W*H) : As per customer requirement Millimeter (mm)

GST : 27AACPM2868E1ZP

Send Inquiry

Send Inquiry Send SMS

Send SMS