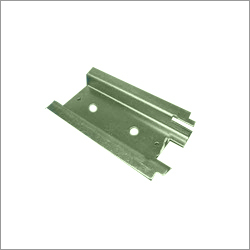

Industrial Sheet Metal Pressed Parts

Industrial Sheet Metal Pressed Parts Specification

- Dimension (L*W*H)

- Custom as per drawing or sample, typically ranging from 50mm x 50mm x 2mm to 500mm x 400mm x 6mm

- Mount Type

- Bolt, Weld, Clip, Screw

- Shape

- Flat, Angled, U-Shaped, Custom Profile

- Coating Type

- Zinc, Chrome, Nickel, Epoxy

- Application

- Automotive, Electrical, Machinery, Construction

- Usage

- Structural and fastening purposes in industrial assemblies

- Surface Finishing

- Matte, Glossy, Smooth, Textured

- Components

- Mounting brackets, Flanges, Covers, Plates

- Weight

- Depends on dimensions and material, ranges from 100g to 5kg

- Hole Size

- 2 mm to 25 mm diameter, custom as needed

- Material

- Mild Steel, Stainless Steel, Aluminum, Copper

- Tolerance

- 0.1 mm to 0.5 mm

- Thickness

- 0.5 mm to 6 mm

- Capacity

- Upto 1000 tons press capacity

- Surface Treatment

- Galvanized, Powder Coated, Painted, Electroplated

- Making Process

- Pressing, Stamping, Punching, Cutting

Industrial Sheet Metal Pressed Parts Trade Information

- Minimum Order Quantity

- 2000 Pieces

- FOB Port

- Mumbai

- Supply Ability

- Piece

- Delivery Time

- Week

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- as per requirements

- Main Domestic Market

- Maharashtra

About Industrial Sheet Metal Pressed Parts

Holding a highly reputed and trusted market standing, we are engaged in manufacturing and supplying Industrial Sheet Metal Pressed Parts. These parts are used in industries like electronics, construction, power generation, automotive and defense. We manufacture these parts at our sound production unit using best quality sheet metals. The parts we provide are free from any internal or external damages & can be customized as per clients requirements. We offer Industrial Sheet Metal Pressed Parts at affordable prices to clients.

Features:

- Sturdy and durable

- Resistant to corrosion

- High tensile strength

Versatile Applications

Our pressed metal parts are suitable for structural and fastening needs in varied industries, including automotive, electrical, machinery, and construction. Their adaptability makes them ideal for mounting brackets, flanges, covers, and more, accommodating diverse design and functional requirements.

Precision Manufacturing

Utilizing modern pressing, stamping, punching, and cutting technologies, we ensure tight tolerances (0.1 mm to 0.5 mm) and consistent quality across every batch. Each component adheres to internationally recognized standards like DIN, ASTM, and ISO, providing assurance of reliability and safety for industrial use.

Customizable Surface and Form

We offer an array of customization options in shape, thickness, edge type, surface finish, and coating type. Available in various coatings such as zinc, chrome, nickel, and epoxy, our products are designed to maximize corrosion resistance and meet the exact specifications of your project.

FAQs of Industrial Sheet Metal Pressed Parts:

Q: How can the sheet metal pressed parts be customized for specific project requirements?

A: Customization is available for several parameters, including shape, thickness, hole size, coating type, surface finish, edge style, and color. Clients can submit drawings or samples to request tailored dimensions and features to suit their projects.Q: What is the process used to manufacture these sheet metal components?

A: These parts are manufactured using advanced processes such as pressing, stamping, punching, and cutting. State-of-the-art machinery ensures high precision, smooth edges, and adherence to international manufacturing standards.Q: When should a specific surface treatment or coating be selected?

A: The choice of surface treatment or coating, such as galvanizing, powder coating, painting, or electroplating, depends on the required corrosion resistance, environmental exposure, and desired appearance. Consulting our technical team can help determine the best option for your application.Q: Where are these products typically used, and what are their benefits?

A: Our sheet metal pressed parts are commonly used in automotive, electrical, machinery, and construction sectors. Their main benefits include high strength, excellent machinability, customization options, and reliable performance in corrosive or high-temperature environments.Q: What packaging methods are used to ensure safe transit and storage?

A: Parts are securely packed in carton boxes, placed on pallets, and protected with bubble wrap to prevent physical damage during transportation and storage. These methods are chosen to match the order volume and size of the components.Q: How long does it take to receive an order of these sheet metal parts?

A: Lead times typically range from 7 to 30 days, depending on the complexity, customization requirements, and volume of the order. Expedited production options may be available upon request.Q: What tolerance and dimensional range are supported for these parts?

A: We offer tolerances ranging from 0.1 mm to 0.5 mm, with dimensions typically spanning from 50mm x 50mm x 2mm to 500mm x 400mm x 6mm. Custom dimensions can be provided as per customer drawings or specifications.

- Minimum Order Quantity

- 2000 Pieces

- Supply Ability

- 4002861 Pieces

- Delivery Time

- Week

- Main Domestic Market

- Maharashtra

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Parts Category

Industrial Precision Stamping Part

Minimum Order Quantity : 1000 Pieces

Material : Stainless Steel

Application : Industrial Machinery

Usage : Hardware Fittings

Making Process : Other, Precision Stamping

Dimension (L*W*H) : 45 mm x 30 mm x 8 mm

Sheet Metal Stamping Parts

Minimum Order Quantity : 10000 Pieces

Material : Other, Stainless Steel, Mild Steel, Aluminum

Application : Automotive Industry, Electronics, Construction

Usage : Mechanical Assembly, Automotive Parts, Electrical Enclosures

Making Process : Other, Stamping, Pressing

Dimension (L*W*H) : Custom as per drawing, typical range 50 mm x 30 mm x 1.2 mm

Sheet Metal Pressed Parts

Minimum Order Quantity : 1000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Application : Automotive, Electrical, Machinery, Construction

Usage : Metal Enclosures, Brackets, Covers, Automotive Parts

Making Process : Other, Stamping/Pressing, Cutting, Bending, Punching

Dimension (L*W*H) : Custom as per design/drawing

Sheet Metal Components

Minimum Order Quantity : 1000 Pieces

Material : Aluminum, Copper, Stainless Steel, Steel

Application : Engineering, Automobile, Electrical Etc.

Usage : Industrial

Making Process : Stamping

Dimension (L*W*H) : As per customer requirement Millimeter (mm)

GST : 27AACPM2868E1ZP

Send Inquiry

Send Inquiry Send SMS

Send SMS