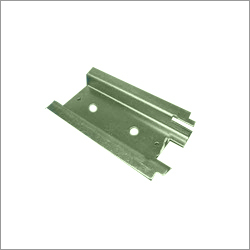

Sheet Metal Pressed Parts

Sheet Metal Pressed Parts Specification

- Coating Type

- Zinc, Nickel, Chrome, Custom

- Application

- Automotive, Electrical, Machinery, Construction

- Dimension (L*W*H)

- Custom as per design/drawing

- Hole Size

- As per drawing/specification

- Surface Finishing

- Smooth, Matt, Glossy, Electroplated

- Usage

- Metal Enclosures, Brackets, Covers, Automotive Parts

- Weight

- Depends on size and design

- Components

- Customized/As per requirement

- Mount Type

- Surface Mount, Panel Mount, Bracket Mount

- Shape

- Flat, Curved, Angled, Customized

- Material

- Mild Steel, Stainless Steel, Aluminum, Copper

- Tolerance

- 0.05 mm or as specified

- Thickness

- 0.2 mm to 12 mm

- Capacity

- Up to 400 Tons Pressing Capacity

- Surface Treatment

- Plating, Powder Coating, Painting, Galvanizing

- Making Process

- Stamping/Pressing, Cutting, Bending, Punching

Sheet Metal Pressed Parts Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Telegraphic Transfer (T/T), Cheque

- Delivery Time

- Week

- Packaging Details

- as per requirements

- Main Domestic Market

- All India

About Sheet Metal Pressed Parts

Advanced Manufacturing Methods

Utilizing CNC machinery, hydraulic presses, and progressive dies, our sheet metal pressed parts achieve precise dimensions, tight tolerances, and complex geometries. Each component undergoes meticulous processes like stamping, cutting, bending, and punching, ensuring high repeatability and consistent quality for industry-specific applications.

Tailored to Your Requirements

We offer comprehensive customization, including material type, size, thickness, and surface treatment. Coating options like zinc, nickel, and chrome, along with various finishesfrom matte to glossyenable the parts to meet your functional and aesthetic specifications. Packaging is adapted for safe transport, whether in carton boxes or wooden crates.

FAQs of Sheet Metal Pressed Parts:

Q: How are sheet metal pressed parts manufactured?

A: Sheet metal pressed parts are produced using advanced techniques such as CNC machining, hydraulic pressing, and progressive dies. The manufacturing process typically involves stamping or pressing, cutting, bending, and punching, followed by surface finishing treatments to ensure high quality and durability.Q: What materials and finishes are available for these parts?

A: These parts are available in materials like mild steel, stainless steel, aluminum, and copper. Finishing options include plating, powder coating, painting, galvanizing, and various coatings such as zinc, nickel, or chrome to ensure corrosion resistance and the desired appearance.Q: When can I expect delivery of my order?

A: Lead times for sheet metal pressed parts generally range from 2 to 4 weeks, depending on the complexity and customization of your design. We prioritize efficient production and quality assurance to meet your timeline requirements.Q: Where are these sheet metal pressed parts typically used?

A: Sheet metal pressed parts are widely used in sectors such as automotive, electrical, machinery, construction, and custom enclosure manufacturing. Applications include brackets, covers, metal enclosures, and various structural or mounting components.Q: What benefits do these parts offer compared to conventional methods?

A: These parts provide high precision, repeatability, and flexibility in design. The rigorous quality standards (ISO, RoHS), robust corrosion resistance, and the ability to tailor dimensions and finishes make them superior for industrial and commercial applications.Q: How is quality and compliance ensured during production?

A: All manufacturing processes adhere to strict ISO and RoHS standards as required by clients. Each part undergoes inspections for dimensional accuracy, material hardness, surface finish, and coating integrity to guarantee long-term reliability.

- Minimum Order Quantity

- 1000 Pieces

- Delivery Time

- Week

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Parts Category

Industrial Sheet Metal Pressed Parts

Minimum Order Quantity : 2000 Pieces

Material : Other, Mild Steel, Stainless Steel, Aluminum, Copper

Making Process : Other, Pressing, Stamping, Punching, Cutting

Dimension (L*W*H) : Custom as per drawing or sample, typically ranging from 50mm x 50mm x 2mm to 500mm x 400mm x 6mm

Application : Automotive, Electrical, Machinery, Construction

Usage : Structural and fastening purposes in industrial assemblies

Industrial Precision Stamping Part

Minimum Order Quantity : 1000 Pieces

Material : Stainless Steel

Making Process : Other, Precision Stamping

Dimension (L*W*H) : 45 mm x 30 mm x 8 mm

Application : Industrial Machinery

Usage : Hardware Fittings

Sheet Metal Stamping Parts

Minimum Order Quantity : 10000 Pieces

Material : Other, Stainless Steel, Mild Steel, Aluminum

Making Process : Other, Stamping, Pressing

Dimension (L*W*H) : Custom as per drawing, typical range 50 mm x 30 mm x 1.2 mm

Application : Automotive Industry, Electronics, Construction

Usage : Mechanical Assembly, Automotive Parts, Electrical Enclosures

Sheet Metal Components

Minimum Order Quantity : 1000 Pieces

Material : Aluminum, Copper, Stainless Steel, Steel

Making Process : Stamping

Dimension (L*W*H) : As per customer requirement Millimeter (mm)

Application : Engineering, Automobile, Electrical Etc.

Usage : Industrial

GST : 27AACPM2868E1ZP

Send Inquiry

Send Inquiry Send SMS

Send SMS